Lessloss Audio

Neu im Programm, nur im Geschäft !

Bei uns anhören, vergleichen oder auch zuhause ausprobieren möglich.

Kabel, neuartige Filtertechnik, Entkoppler, Entstörtechnik uvm.

Kein Versand.

Großer WORKSHOP sobald wieder erlaubt !

C-MARC™ Interconnect Cables

C-MARC™ Digital Cables

C-MARC™ Speaker Cables

C-MARC™ Power Cables

C-MARC™ Entropic Process Power Cables

Firewall 64ox Power Conditioning Module

Firewall for Loudspeakers Signal Conditioning Module (Blue Moon Award!)

Blackbody v.2 Ambient Conditioner

Bindbreaker High Performance Isolation Feet

Echo's End Discrete Precision Resistor R-2R Ladder DAC

Firewall for Loudspeakers Production, or How DARPA missed the Audiophile Boat

Years of Effort

The LessLoss Firewall has gone through a lot of research and development since its inception. What began as a novel idea about implementing Skin-filtering by exploiting the naturally occurring Skin-effect of current running through a wire has been expanded upon many times since its inception. Today we are actually using field structuring around the conductor in unique ways. The Firewall 64X is a LessLoss proprietary technology, based on precisely positioned directional metallic particles within a thermoplastic carrier. The result becomes kind of a micro-transformer. Kind of a ferrite core filter. Kind of a directional set of A/C diodes. Very much kind of a near field Blackbody for signals. That pitch black background, so important to stable "3 AM" type sound quality, is getting set to a higher and higher bar at every step of our way. People keep asking, 'Can it really get any better than this?' Answer: you bet! When the Firewall for Loudspeakers is connected to the signal at the speaker terminal, it brings a cosmic change to the sound quality.How do we make it?

Well, we don't. We assemble it. The core production of our proprietary technology is carried out by a certified specialty lab by men in what can only be described as hazmat suits. This is actual photography from their state-of-the-art facilities:

The above machine makes the proprietary Firewall components.

How is it done?

It's done by laser.Direct Metal Laser Sintering (DMLS), also known as Laser Powder Bed Fusion (LPBF), is an Additive Manufacturing (AM) technique designed to use a high power-density laser to melt and fuse metallic powders together. This process has the ability to fully melt the metal material into a solid three-dimensional part, unlike Selective Laser Sintering (SLS).

SLS was originally developed in the mid-80's under sponsorship of DARPA. This process has the disadvantage that resulting parts have porous surfaces. Expensive post-processing methods such as Hot Isostatic Pressing are required to reduce the pores. In other words, the parts must be placed in a high pressure argon atmosphere and raised in temperature, then quickly and uniformly cooled, in order to achieve stability and reliability.

More advanced than DARPA?

We are using an even more advanced system, called Direct Metal Laser Sintering (DMLS). Research on this process began in 1995 as a German research project at the Fraunhofer Institute. This new technology was first commercialized in 2000.Since the components are built layer by layer, it is possible to design organic geometries, internal features and challenging passages that could not be cast or otherwise machined.

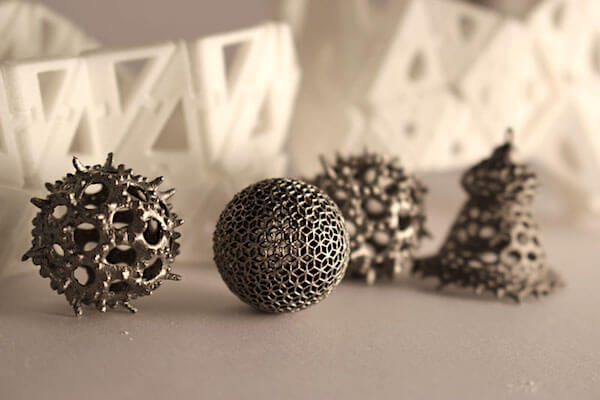

Below are actual objects made by our production partners using this innovative, state-of-the-art DMLS process. What's fascinating about the design freedom enabled by this advanced technology is that you can make objects nested into objects, with surfaces and internal voids which would otherwise be absolutely impossible to make.

In fact, you could, if you wanted, make all of the above objects placed, quite literally, inside one another. Meshed with one another. Even turned Inside out. This was not possible before.

Hey, we can use this!

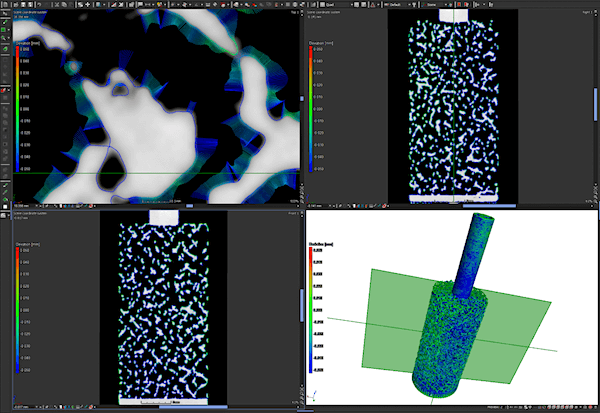

That's where LessLoss comes in. Our solutions are so uncommon, that even the 3D laser production guys had to produce at least 80 prototypes before they mastered nuances such as repeatability, precision, scale and visible and non-visible surface demands. They use the most advanced software available such as Solidworks, so going back and forth from accountably accurate changes was only a matter of fortitude.

The computer process slices the 3D CAD file data into many ~20 micrometer thick layers. The thin layers are, one by one, selectively smelted by the laser which is located in a tightly controlled atmosphere of argon gas. Believe me, this is no desktop operation. Oxygen levels must be kept lower than 500PPM to prevent explosion. The high-power ytterbium fiber laser beam is literally hundreds of watts strong. The laser energy is intense enough to permit full welding of the particles to form solid metal, without creating a porous internal structure.

The brains, heart and soul of the new Firewall for Loudspeakers

The new Firewall for Loudspeakers is so effective because in designing it we did not ask the typical questions. We asked fundamentally different questions and came up with fundamentally different answers.This product is not about what the amp sees in terms of impedance or load. This is no Zobel network or other invasive technology. What the speaker does in conjunction with the amp remains absolutely the same as before.

In terms of electrical performance, what the amp will "see" per polarity when sending its signal through the Firewall for Loudspeakers is a 16mm^2 cross section of pure copper, which is incredibly high conductivity, much higher than most any loudspeaker cable, and certainly more than any internal wiring of any loudspeaker. So, in no way does the Firewall for Loudspeakers impede dynamic signal flow, nor does it influence the impedance of the speaker that the amp sees. In flowing through the Firewall unit, the signal is conditioned without ever influencing its resistance at all, at any audio frequency. This has a profound effect because only the most natural results follow, without any adverse effects to micro-dynamics. The amp (any amp in fact) will continue to perform in conjunction with the speaker exactly as it did before. The resulting sound quality, however, is greatly improved.

Our approach can be split up into three basic terms.

(1) The brains (unique in-house controlled copper processing),

(2) the heart (proprietary Firewall noise reduction solution)

(3) and the soul (special assembly approach).

A perfect balance of the three, all three being exemplary and far beyond the typical scale for audio solutions, results in a magnificent boost in sonic performance. Let's take these three and unpack them.

(1) The Brains

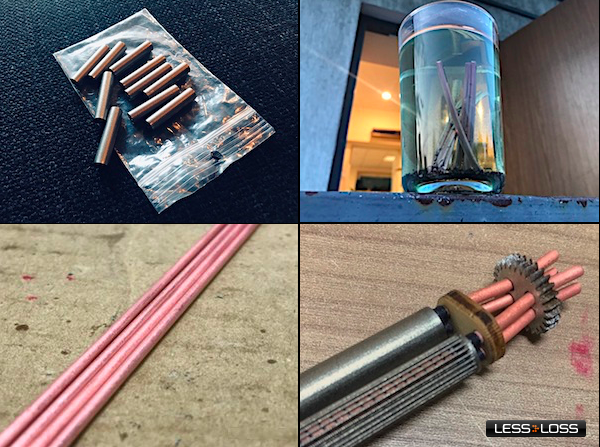

In standard extrusion processes, the copper undergoes many forces until the desired size is achieved. Pictured at the top of the image below, you can see a standard copper wire as extruded using industrial methods. Next to this standard copper wire, you can see our copper that we use in the Firewall for Loudspeakers. It is a completely different beast. This is created in house through proprietary means.

LessLoss proprietary copper sourcing and in-house processing creates absolutely purpose-specific raw material which undergoes absolutely no tension or forces other than those which are specific to each polarity of our design. Thus, the positive and negative Firewall for Loudspeakers units are completely different from the very inception of the individual conductor material used. This is no typical exercise in choosing different off-the-shelf metals for positive and negative polarities to get a 'house sound' deemed 'nice.' It goes much more fundamentally into the nature of the material itself. We come intriguingly close to dancing with the concept of brownian noise itself.

This time-consuming and fundamental level of detail adhered to in production creates a material (seen here next to standard copper) which bears a physical malleability closer to that of lead (or even butter), than industry sourced copper. Thus, even its acoustic properties are fundamentally different than those of standard copper. Industrially annealed copper, known as 'soft,' does not even come close.

In slightly different lighting, this image shows in direct comparison how different our in-house made raw material is from standard copper. Standard copper, even soft annealed type, withstands considerable pressure. Our special material does not at all and must be handled with the most extreme care.

99.99999999999999999%... ad absurdum

We have painstakingly investigated the tie between copper purity and resulting audio performance. You will see much talk in the audio world about the so-called 'nines race.' Through direct consultation with several metallurgy labs which determine metal purity with governmentally recognized certification processes, these bearing legal status, we have no doubt that this type of claim is complete bogus. In fact, there is no certification laboratory on earth which will certify any purity higher than the industry standard 'four nines,' which means 99.99%. Anything you see over and above this in terms of purity is pure fiction. And even the four nines purity cannot be guaranteed for an entire spool. Buyer beware.What we have established through our fundamental investigation is that, in fact, it is not the purity in terms of material analysis which yields the performance we are aiming for, but rather the purity of the process. For it is easy to take the purest copper, process it according to our advanced proprietary methods, assemble it specifically incorrectly, and the resulting sound quality will be far worse than using run-of-the-mill industrially sourced re-cycled copper which boasts no exotic purity at all. These types of tests prove without doubt that people have been asking the wrong questions and have been looking in the wrong place for sonic bliss.

We take pride in this proprietary knowledge which allows us to boost performance to unworldly levels far beyond what any fictitious 'nines race' leader can even dream of achieving.

(2) The Heart

The heart of our solution is the special Firewall technology we have been constantly working on and perfecting for over a decade now. Again, due to the proprietary nature of the solution, we cannot delve too deeply into its every intricacy. But we can explain how it is made.It is made by laser. Direct Metal Laser Sintering (DMLS), also known as Laser Powder Bed Fusion (LPBF), is an Additive Manufacturing (AM) technique designed to use a high power-density laser to melt and fuse metallic powders together. This process has the ability to fully weld the metal powder material into a solid three-dimensional part of any conceivable shape or form.

We are using the most advanced AM system called Direct Metal Laser Sintering (DMLS). Research on this process began in 1995 as a German research project at the Fraunhofer Institute. This new technology was first commercialized only in the year 2000.

Since the components are built layer by layer, it is possible to design organic geometries, internal features and challenging passages that could not be cast or otherwise machined.

A computer process slices the 3D CAD file data into many ~20 micrometer thick layers. The thin layers are, one by one, selectively smelted by the laser which is located in a tightly controlled atmosphere of argon gas. This is no simple desktop operation. Oxygen levels must be kept lower than 500PPM to prevent explosion. The high-power ytterbium fiber laser beam is literally hundreds of watts strong. The laser energy is intense enough to permit full welding of the particles to form solid metal, without creating a porous internal structure.

Any approach to the machinery must be made wearing protective gear, as seen below in an image of the very people working on our Firewall production.

Magnified many times, below you can see the implementation of the latest Firewall technology in conjunction with our special in-house designed raw copper rods. Because the Firewall is made by laser, extremely fine details of design can be taken advantage of, resulting in a very sensitive part. We could not deliver this product and provide reliable long-term results in the exposed form as pictured below. Through simple usage, it would quickly bend or break up and lose its physical integrity. The copper is rather like a soggy noodle which has been out in the sun for a few hours.

Careful assembly techniques need be established because any maladjusted move results in immediate compromise to this delicate solution. These techniques require special tooling custom manufactured for LessLoss to enable a rational assembly method and to keep costs down.

(3) The Soul

When the brains and heart come together, in strict fashion according to our best knowledge resulting from years of countless experiments and discoveries, the soul of the device shines through. The transparent housing refracts the ambient light creating optical illusions of a fantom third Firewall inside. Continue turning the cylinder and at times it can even appear that there is no wall thickness.This approach takes care of two things. Firstly, structural integrity of all of the sensitive components is maintained, even if you throw this device around or drive on it with an industrial vacuum cleaner. It is rock solid to the user, and liquid soft to the signal. Secondly, the lack of any colored material surrounding the active portion of the Firewall guarantees the most natural sound quality possible.

As in any refined balancing act, too much of any one ingredient will inevitably color the outcome. The closest thing to a total absence of coloration is the least electro-magnetically filtering material, which means in this case absolutely pure transparency. This allows the perfect conditions for the new Firewall for Loudspeakers solution to really shine. Magnificently so, as you will instantly hear.

Of course, with a solution so effective and mature, we need a flexible umbilical of the same uncompromising performance. C-MARC™ cable is the only choice for this, of course. Nothing even comes close in terms of purity, naturalness, and silence of operation.

One listen, and you'll see why.

How about bi-wiring applications? How will the Firewall connect in such cases?

If you are using bi-wiring, such that you have two sets of loudspeaker cables between amp and each speaker, it is still advisable to use one Firewall for each terminal input. You can not use this Firewall for Loudspeakers on the amp output between amp and cable. The direction of signal will in that case be wrong and it will not function as designed.If your speakers have one pair of +/- terminals for 'High frequency' and one set of +/- for 'Low frequency,' you should be using a Firewall on each of these four terminals per speaker. In those instances, for a stereo setup involving two loudspeakers, the total needed is eight individual units. This means you will need two complete stereo pairs of the Firewall for Loudspeakers product. One stereo pair is made up of four units, and two stereo pairs are made up of eight units.

The positive terminal units differ both internally and externally from the negative terminal units. These differences are clearly marked so you will never inadvertently make the mistake of mixing up positive with negative. Polarity makes a huge difference as it is fundamental to its operation.

Is it advantageous, as is the case with the Firewall 64X for power, to daisy chain two in series?

It is. Definitely.Is the Firewall for Loudspeakers product merely an application of the existing Firewall 64X for power?

Absolutely not. We always strive our hardest to offer only the latest, most advanced art we are capable of. The Firewall for Loudspeakers is a different beast altogether and these two should not be confused.

Just as the DFPC Reference is a highly effective upgrade to the DFPC Original and Signature, the Firewall Module represents the ultimate upgrade for use with any of the DFPC power cords. Where the DFPC leaves off, the Firewall Module takes over. Because the short lead of the Firewall module is highly flexible, it can make installation even easier regardless of circumstances. One can exchange existing traditional power filter technology based on resonance for Firewall modules, and thus obtain the ultimate audiophile sound quality, at a much lower cost.

The Firewall module is an efficient, lightweight, low cost alternative to heavy, costly power filters. Almost every customer winds up exchanging existing traditional filtering technologies for Firewall modules.

The Firewall Module does not color the sound nor influence dynamic performance. Unlimited sound quality improvement is available through daisy chaining multiple units in series. Fear not that one might achieve overkill should multiple units be used together. That built-in deficiency is the realm of traditional filtering technologies built on caps and coils. Traditional filtering is based on resonance of a limited bandwidth. And, as it turns out, that is indeed the very definition of a color. LessLoss Skin-filtering exhibits no resonance of this kind, and, thus, does not color the sound.

If using power distribution units: we recommend using units containing no internal fuses or traditional filtering elements (e.g., capacitors, chokes or transformers). Customers report excellent results using Furutech model e-TP60.

The Firewall Module is an excellent component isolator. The filtering provided to the power of a system can equally well be used to provide isolation of noise from one piece of equipment to another. Typically, digital source gear tends to be the most noisy to the rest of the gear in the system sharing the same power line. To separate these, multiple Firewalls are recommended, and they will all effectively filter in both power flow directions, bringing the system’s performance as a whole to unprecedented levels.

In application, the Firewall was conceived as a modular system: we’ve designed it to be used in a variety of ways in a variety of systems, maintaining a very low cost of introduction. This way it provides maximum usability and ease of incorporation into any system’s space and performance requirements.

More on the Firewall Module

The LessLoss plug-and-play Firewall Module power conditioner features a C14 inlet and a C13 plug, for direct connection between a power cord and your equipment. Through simple connection, your existing equipment's performance matures to an entirely new level, regardless of make.The enclosure is milled from two pieces of solid oakwood. For superb micro-vibration control, the C14 inlet is mated directly against the natural oakwood enclosure. No metal housing can provide this type of performance, regardless of the use of even the most exotic rubber damping. Aluminum is particularly harsh on sound quality, lending a type of unavoidable artificially etched ’hi-fi’ type sound. The Firewall module contains no aluminum whatsoever, and facilitates an organically rich, natural sound quality.

The attractive antique oakwood enclosure contains the Firewall electronics themselves, which are mated directly to its inner hardwood surface to obliterate micro-ringing directly at the source of action. Any time an electromagnetic current runs through a wire, some amount of micro-vibration occurs due to resistance. Our solution deals comprehensively with both electromagnetic as well as low level acoustic noise. At this level of performance, both must be taken into account in equal measure if the solution is to claim maturity.

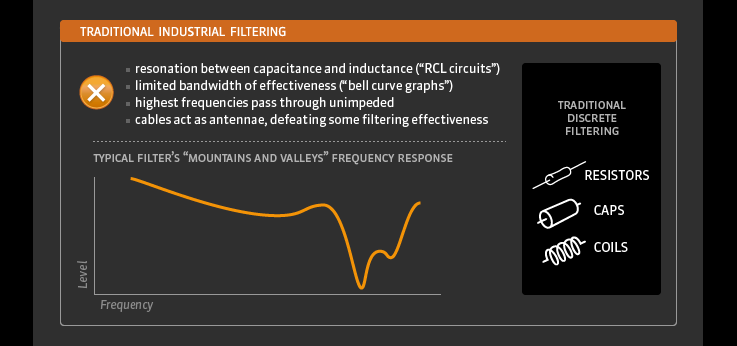

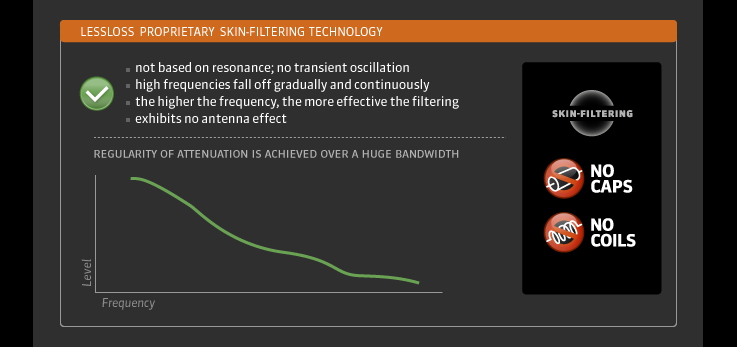

LessLoss Skin-filtering is our advanced proprietary noise reduction technology which leaves standard cap-and-coil filtering methods far behind. In fact, the use of our technology reveals shortfalls of standard filtering methods and can therefore replace them altogether.

The Firewall module features our most advanced LessLoss modified C13 plug. It has a much tighter grip than the standard version. This translates to a stronger electrical contact pressure with rock solid control of sound. No brass is found in the signal path. A special prolonged cryogenic treatment process is carried out which lends a relaxed, natural tone quality revealing the most natural details. The clear body is no accident: color agents all introduce their own fingerprint on to the sound. This solution is completely in line with our colorless Skin-filtering process. Together with superb micro-vibration damping and cryogenic processing, the Firewall module is the best gateway for any equipment to receive high quality power. Without quality power, audio performance is limited even by the most exquisite gear.

Use the Firewall module with any equipment so that its potential performance can be realized in today’s over-polluted electro-magnetic atmosphere. Every recording contains layers and layers of emotionally charged valuable data which remain entirely hidden from the listener unless the power is properly conditioned. Through LessLoss Skin-filtering technology, power is stripped of noise and dynamics are never compromised in the process. The product is lightweight and simple to install. Its low price and extremely high performance make it unique.

LessLoss Skin-filtering does not color the sound nor influence dynamic performance. Before considering costly power supply upgrades involving large film capacitors or heavy silver wound coils, keep in mind that their ultimate performance is limited by the losses involved in the filtering method itself. Traditional filtering is based on resonance between capacitance and inductance. With the LessLoss Firewall Module, upgrading your equipment has never been more cost-effective or easy. Our plug-and-play Firewall modules raise the performance level of any audio or video equipment far beyond the realm envisaged by their original designs.

At the heart of its functionality, the Firewall Module features our tried and tested Skin-filtering technology upon which our power cables are based. Skin-filtering makes perfect use of the way that alternating electrical current naturally travels down a wire. Its functionality is based on the principle of attenuation over distance, and on the high-frequency skin effect first described mathematically in 1883. Users the world over attest to the supremacy of this technology when comparing to traditional power filtration methods based on the resonance of capacitors and inductors.

Because nature determines that high frequencies reside at the skin of every conductor, it is easy to understand why LessLoss Skin-filtering is the audiophile’s best and most efficient tool to condition the power before it enters his or her audio component. Treating the skin of the conductor attenuates HF noise, preventing it from entering your gear. Because this filtering solution is employed only at the skin of the conductor, the solution never restricts the low frequency power flow your gear relies on. This way you get enhanced HF attenuation without compromising dynamics or coloring the sound.